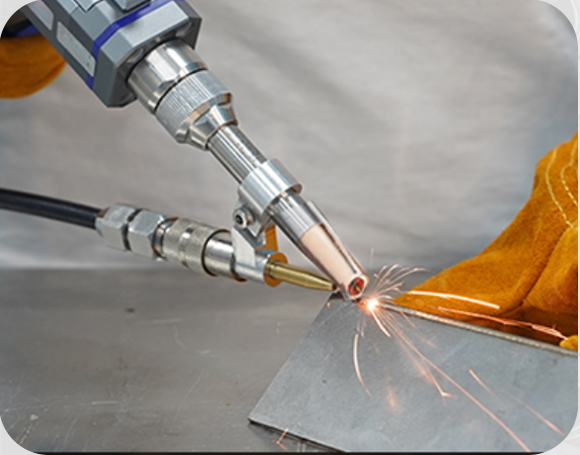

With the rapid development of the 激光焊接机 market, many traditional welding processes are using hand-held laser welding machines. The laser welding machine is mainly aimed at the thin plate field. Compared with the traditional equipment, it has great advantages. It has the characteristics of high welding efficiency, good quality, and simple operation.

Early handheld laser welding machines used water cooling for heat dissipation, which is simple in structure and easy to maintain.

然而, in the process of use, the market gradually found that the water-cooled hand-held laser welding machine has shortcomings in portability and functional ductility. 同时, the characteristics of anti-freezing in winter and anti-condensing in summer also increase the difficulty of equipment maintenance.

As the market demand becomes more sophisticated, some manufacturers have begun to consider using air-cooled solutions as hand-held laser welding machines.

Compared with the water-cooled solution, the hand-held laser welding machine using the air-cooled solution does not require additional water-cooling equipment, which reduces the size and weight of the equipment, and also provides convenience for the later addition of cleaning, cutting and other functions.

Air-cooled handheld laser welding is the key to further replacing the argon arc welding market with greater cost-effectiveness and more flexible application scenarios (small size, portability, and extended functions).

Commonly used handheld laser welding machine prices in the Market

When you do a search online, you’ll come across a lot of different prices for hand held laser welders.

Some machines are priced under $1,000, but others can cost as much as $50,000.

When you go online, you get confused. If you want real results and answers, it’s best to contact the manufacturer and ask them the price of the device.

Different manufacturers Factory offer different prices. They can’t possibly have a median interest rate. A rough estimate of its cost would be around $6,000 到 $15,000 for a mid-sized Handheld Laser welding machine.

High-tech and advanced handheld laser welder machines priced above $15,000 but below $25,000

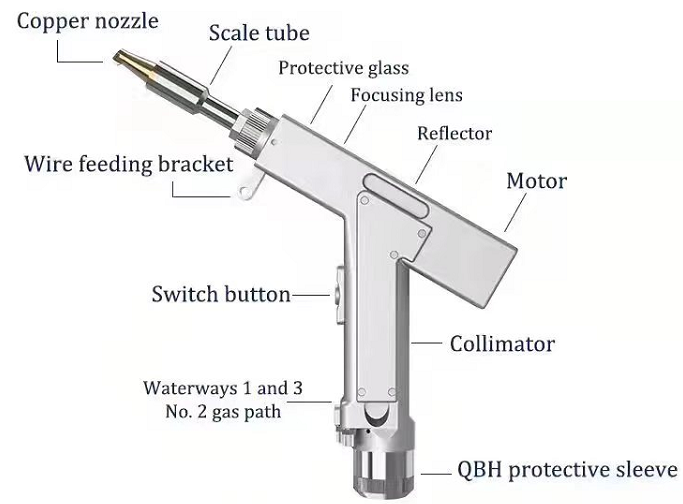

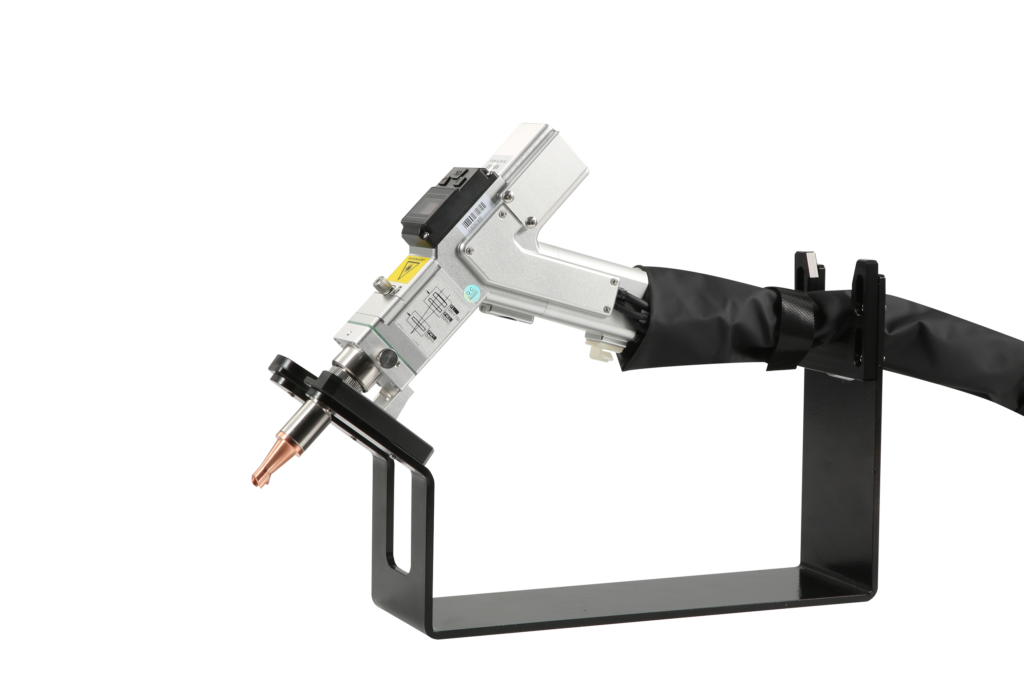

Parts of a Handheld Laser Welder Machine

In order for you to fully understand a handheld laser welder Machine, you need to know its parts.

The main components of the laser welding Machine 包括

#Main control system

#Air cooled

#Machine Switch

#Screen or control system

#hand-held laser head

#Fiber Laser Source

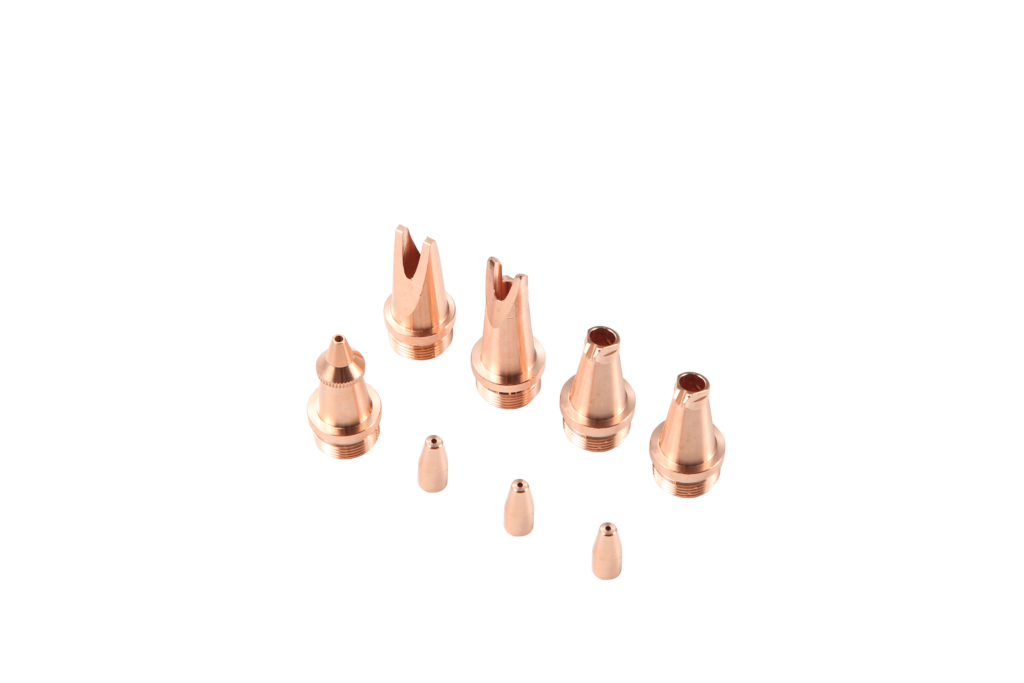

手持式激光头由以下部分组成:

#主开关或按钮

#铜喷嘴

#防护镜片

#聚焦镜

#反射器

#QBH保护套

纤维有什么优点 Laser welding machine?

激光焊接可以给您带来很多优势.

其中最常见的包括: 最高的准确度和精确度

即使您正在焊接小零件和组件,手持式激光焊接机没问题.

焊机一致性

因为你手动设置速度, 电源、模式等, 您可以预期您的焊缝将是一致的 – 即使您需要焊接大量工件.

结合您可以更快焊接的事实, 所以激光焊接机确实是您的首选

一些焊接技术, 例如 MIG 焊接和 TIG 焊接, 不太适合复杂的焊接; 这是由于可用电极数量有限.

就在那时,光纤激光焊接将其提升了一个档次. 无论焊缝看起来多么复杂, 激光焊接机都能做到.

更强, 更耐用的焊缝

最后但绝对不是最不重要的一点是,您可以获得更坚固的焊缝.

您可以使用需要电线或不需要电线的填充材料对其进行焊接, 提供卓越的强度和耐用性.

可移植性

尺寸小且重量轻. 因此, 这使得它对于现场和异地操作都很有用. 用它, 您可以精确地焊接具有复杂设计或大型零件的零件.

多功能性

它与多种材料类型兼容. 此外, 它适用于不同和相似的材料. 然而, 对于异种材料, there is a need to check for material compatibility using their chemical and physical properties.

焊接速度

Laser welding system generally has a fast welding speed due to the highly concentrated heat source. 因此, they are the better choice for production efficiency.

Heat Input

Compared to other methods, the handheld laser welder’s low heat input makes them ideal for joining thin, delicate parts. Other methods can lead to charring and dimensional inaccuracy.

Handheld laser welders also have their shortcomings, including the following:

Initial Investment

The cost of running a handheld laser system is quite high. In addition to the initial investment, the maintenance fee and labor cost contribute to the overall expenses associated with this machine.

Power Output

Compared to other methods, 手持式激光焊机的功率输出相对较低,这可能是一个优点,但在焊接效率方面存在缺点.

这些只是激光焊接最受欢迎的一些好处.

常见的传统焊接技术有哪些及其工作原理?

以下是传统的焊接技术及其工作原理:

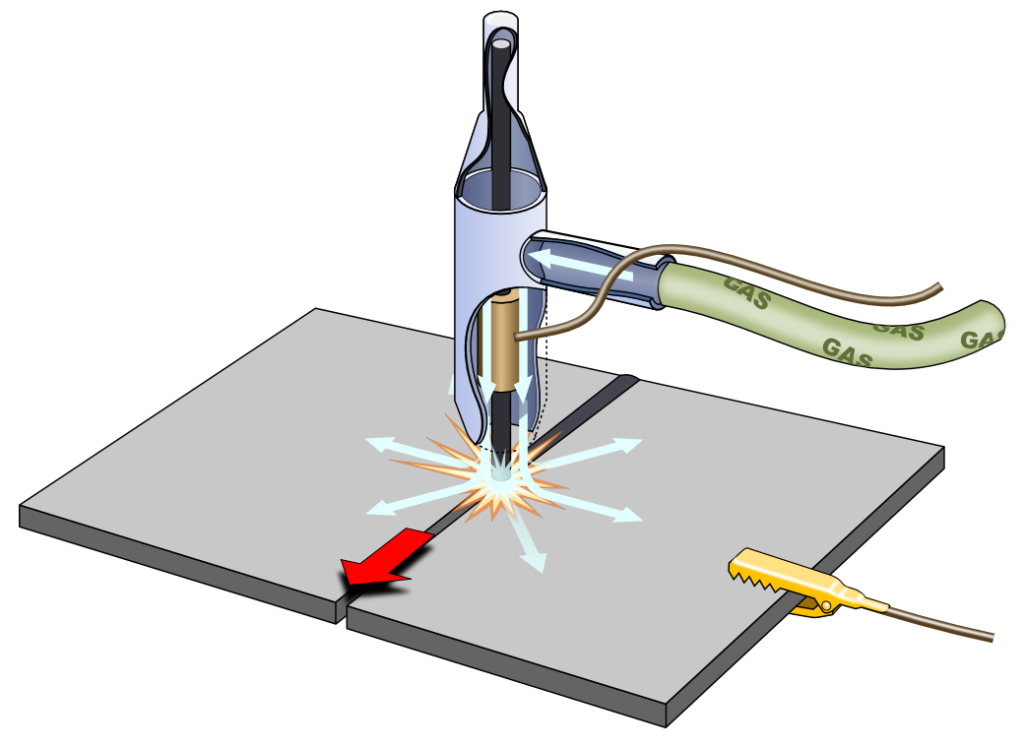

传统焊接

· 金属惰性气体保护焊 (我)

这种焊接技术通过将填充物熔化到相邻部件形成的焊接接头中来焊接两种材料. 直流电 (能量源) 创建弧线, 因此焊接技术的名称.

通常, 直流电是提供电能的电源,可熔化填充材料,同时在工件中产生电弧. 正在冷却, this joins the two materials.

Concurrently, an inert gas, usually argon and helium, travels through the welding head. These gases shield the weld zones from atmospheric contamination. Its efficiency and creation of uniform and clean seams make it suitable for welding parts in industries that deal with manufacturing and fabrication.

· Tungsten Inert Gas Welding (氩弧焊)

TIG welding uses a tungsten electrode as a filler material. The filler material is unique such that it does not melt. It only supplies the heat which melts the workpiece and joins them on cooling.

TIG welding also uses shielding gas such as helium and argon. 此外, the created welded joint is strong. 因此, they are suitable for joining structural parts.

· Shielded Metal Arc Welding (焊条电弧焊)

这种焊接技术使用预涂焊剂的电极来形成电弧. 如 MIG 焊接, 电极熔化材料表面,同时充当填充材料, 形成熔池. 还, 熔化时的助焊剂涂层无需外部保护气体,从而提高焊接质量, 留下高机械强度的接头. 电极类型和焊剂成分各不相同. 基材特性和焊接参数影响选择过程.

· 氧乙炔焊接 (OAW)

氧乙炔焊接使用氧气和乙炔气体将金属连接在一起. 乙炔气, 碳和氢的组合, 是一种燃气. 有氧气存在的情况下, 乙炔气体燃烧并产生高温火焰,其温度足以熔化大多数金属. 两种气体的比例正确, 氧乙炔提供灵活高效的焊接操作.

此外, 氧乙炔焊接工艺主要用于高熔点金属. 然而, 它还可以针对非金属材料进行优化, 包括热塑性塑料和玻璃. 重要的是要注意控制温度,因为过热可能会损坏材料的结构.

传统焊接技术: 的优点和缺点

考虑TIG, 我, 与其他传统焊接技术相比,原因如下:

· 运营成本

上述许多传统工艺都是具有成本效益的选择. 运营成本较低,不会对公司财务产生重大影响. 这些机器价格实惠,不需要大量投资来培训操作员. 此外, 许多企业都可以轻松使用它们.

· Weld Strength

These processes can create more durable welds. The heat generated by the welding arc gets transferred to the base material quickly. This creates a strong bond that can withstand stress and vibrations.

· Versatility

Most conventional welding methods are versatile as they can produce temporary and permanent welds on metals, thermoplastics and glass.

· Material Thickness

The total heat input is high, which makes them suitable for thick materials.

Conventional welding has some shortcomings, which include:

· Part Deformation

Most of these conventional methods are associated with an unintended heat transfer to the surrounding material. This high heat-affected zone area deforms thin materials and parts.

· Welding Rate

The arc welding method is time-consuming. It requires multiple passes to complete a single welding operation. 此外, most welds require post-welding grinding to remove surface irregularities.

Handheld Laser Welding Vs Traditional Welding

Maybe you want to know what are the benefits of a handheld laser welding machine?

Let’s move on to the benefits handheld laser welding machine.

better control

Control from mode, 速度, power, heat, ETC。, control in machine motion. You can set it to the minimum or maximum value according to your Used

No electrodes required

We also know that you don’t have to use electrodes of any kind for this. 所以, you can expect to reduce the cost and loss of output.

Easy to focus

这 handheld laser welding machine laser beam you will use for welding or cutting is easy to focus.

You’ll have optics as a calibration guide, and you’ll never have to worry about quality.

Cost and Ease of Use

Handheld laser welding machines come with a relatively high investment. 此外, the servicing and maintenance fees are also considerably more compared to the traditional methods.

Regarding ease of use, traditional methods require technical expertise, which can increase operating costs. 此外, handheld laser welders have easier to use. Some models even feature automation which increases operational use.

Speed and Production Efficiency

With a faster heating and cooling rate, handheld laser welders are better than traditional methods. 因此, they are more efficient and productive in terms of small-scale welding. 然而, in large-scale welding, traditional methods are more suitable due to the higher long life compared to laser welders.

热影响区 (热影响区)

焊接接头周围温度明显升高的区域也区分了不同的焊接工艺. HAZ 更小,因为激光焊接是一种使用聚焦激光束的非接触式工艺.

另一方面, 大多数传统焊接技术产生的热量会广泛影响周围的材料. 这可以通过再结晶改变金属的微观结构, 相变和沉淀. 此外, 传统焊接方法的热影响区面积不同. HAZ MIG 焊接产生的热量相对较大,因为它具有较高的热输入.

精度与控制

激光焊机的控制水平取决于自动化水平. 尽管如此, 操作员拥有完全控制权. 这比传统焊接技术更好, 其精度较低, 没有自动化, and require high control and focus.

此外, the accuracy and precision of the final weld made with traditional methods may be lower. 然而, using a highly skilled operator can overcome this shortcoming. By overseeing the process, the consistency of the final weld may be similar to laser welds.

材料兼容性

Laser welding has wide material compatibility, although it is more suitable for thin parts. The smaller heat-affected zone they produce makes them the method of choice for delicate and heat-sensitive materials.

另一方面, the material compatibility of traditional techniques depends on the method used. Most are strictly for joining metals and may be less effective for non-metallic materials. 然而, traditional welding techniques are better for very thick parts because of their high heat input.

Applications

尽管制造和维修操作使用不同的焊接方法, 它们在行业中的应用有所不同. 手持式激光焊接机更适合小规模焊接以及薄型材料的焊接。, 精美的, 或复杂的设计.

然而, 传统方法, 尤其是米格焊接, 更适合底盘和车架. 此外, 电弧焊在电子工业中的应用有限,因为它会不可逆转地损坏电子元件.

其他好处包括:

无需真空或辐射防护

可以在小范围内工作

可以在狭小的空间内操作

结论

手持式激光焊接机在多个零件制造行业中越来越受欢迎. 与传统焊接技术相比,它们有一些优点和缺点. 因此, 他们有不同的应用. 本文比较了两种焊接系统, 告知您为您的项目选择合适的产品. 如有任何问题, 有关不同焊接方法的信息请联系我们.

许多人选择自动激光焊接机而不是手持式焊接机. 虽然这样也好, 最好手动启动它,因为你也会从中学到很多东西.

您应该选择哪家手持式激光焊接机制造商?

在手持设备的海洋中 激光焊接机制造商, comwelder 机器位居榜首.

几十年来我们一直引领行业, 我们从未以高退货率让客户失望过

您可以从我们这里购买很多激光焊机 – 不仅仅是激光焊接机. 还有几台光纤金属激光切割机, 珠宝焊接机, 珠宝切割机, 和雕刻机.

机器特点:

电光转换率高, 节能环保;

高输出功率和卓越的光束质量;

高稳定性, 高可靠性, 使用寿命长;

全纤维结构, 结构紧凑, 免维护, 低成本;

特殊制冷方案, 风冷设计, 减少能源消耗, 并保证稳定、长期的发光;

采用模块化设计, 重量和尺寸远小于目前同类产品

最大功率1500W, 穿透深度大于 4 毫米