An appealing hand-held laser welding option for metal fabrications

Technological advancement in laser machines has enabled Businesses make innovative decisions to stay relevant every day. These technologies are being implemented to overcome the shortcomings of traditional methods. For many years, the CO2 laser and pulsed Nd: YAG have remained the only laser of choice to bring them to the workplace.

Since more applications demand a higher precision control, lower heat input, and lower electrical energy consumption, Handheld Fiber Laser Welding technology such as ComWelder B1 takes a significant step forward and becomes a viable welding solution to boost productivity and improve customer satisfaction.

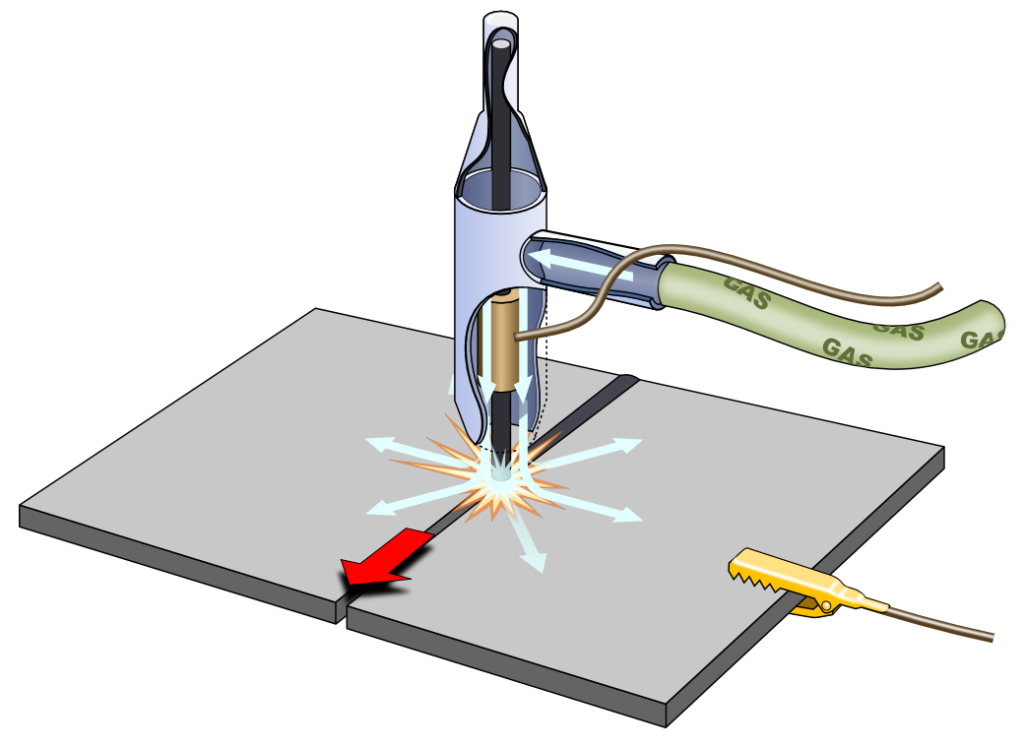

It employs a high-intensity laser power to generate the heat required for welding. The concentrated heat source enables fine, deep welding and high welding speeds. An optical fiber cable delivers the laser beam to theLaser head, which then focuses it on the surface, resulting in a molten pool along the joining path of the objects, causing fusion upon solidification.

If you’re interested in finding out the best fiber laser welding machine, don’t miss out on this comprehensive guide that will walk you through the ComWelder B1 fiber laser welding detail from beginning to end.

Why ComWelder B1? Advanced, Unbeatable, and Compelling Features

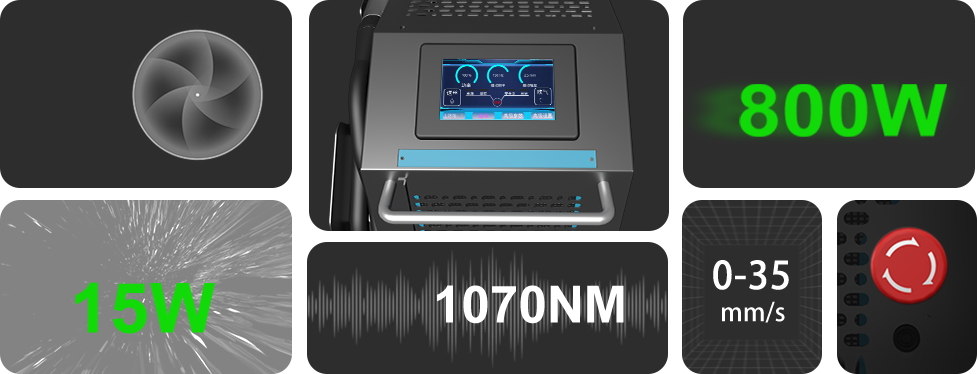

ComWelder B1 Fiber laser technology is an easily saleable laser in a compact form with 800W power capacity. The output power of a B1 fiber laser far exceeds the commercially available Nd: YAG laser technology while offering <1.1 beam quality.

The fiber laser welder is more flexible for implementing the flexible transmission of non-contact welding for those difficult-to-weld sites. It offers Fast welding speed 4-10 times faster than traditional welding. In fact, fiber beam quality and laser power are far better than CO2 and other solid laser.

those of CO2 lasers.

ComWelder B1 comes with various detection and protection facilities that greatly avoid the faults caused by multiple external factors or human misuse, ensuring the equipment provides safer, user-friendly, and long-term stable operation.

The automatic alarm setting provides a weld control monitoring system that detects the air pressure and volume and offers responsive, useful outputs indicating the quality of the weld. The B1 welding apparatus features a safety clip, which means that the machine is only effective when the clip is connected with welding materials. This ensures a closed circuit for the welding process and guarantees safety for the operator.

The ComWelder B1 laser welding machine can process welding operations on materials such as carbon steel, stainless steel, aluminum plate, copper, Brass, and other metal sheets.

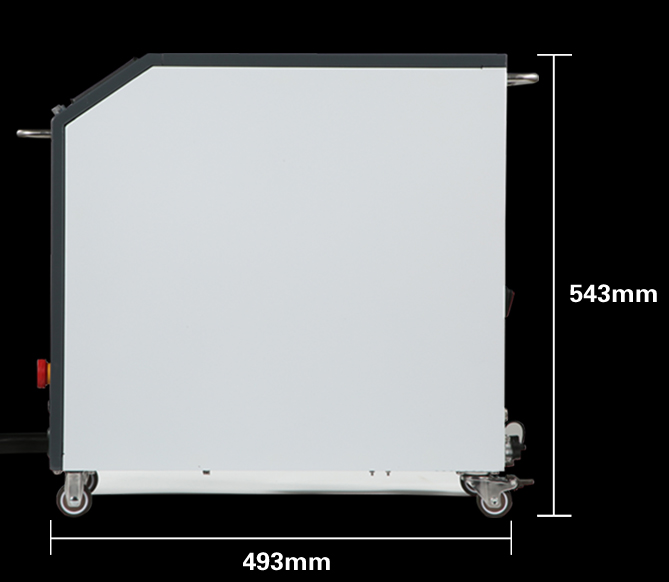

It is equipped with a safety circuit to avoid false light emission. It features a push-pull handle with universal wheels at the bottom to ensure the collective structure is compact and easy to operate.

It comes with adjustable nozzles of various angles to meet the welding requirements of multiple products.

1. Environmental Protection and Energy Saving

Since Welding has become one of the most prominent manufacturing processes, the major botherable concern is the high amount of yearly resource consumption for providing power for welding.

ComWelder has incorporated high-performance chips into their welding processes, significantly reducing the heat input required for operation. This innovative approach minimizes the secondary energy consumption caused by heat dissipation.

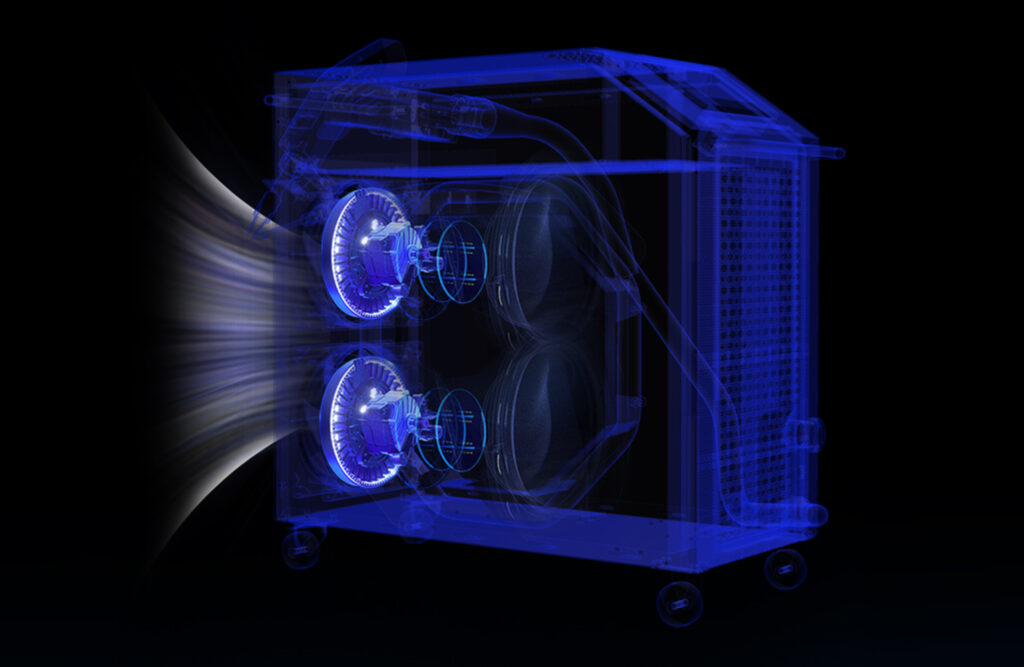

Another compelling element of the B1 laser welder is the in-built air cooling system that helps maintain the optimal performance and longevity of the laser source.

The air cooling technology in ComWelder B1 uses components like inverter fans that, on one side, provide cooling to the radiator and simultaneously cut down more than 65% on the power consumption.

This aims to enhance air convection and complete heat exchange inside the machine. When the laser is operating, the inverter fan rapidly rotates, blowing air into the radiator and dissipating the heat through convection and radiation.

This cooling method is simple and effective and is a game changer.

2. Compact Design For Modern Needs

The components of the ComWelder B1 laser welding machine are well accumulated in a compact portable unit, largely minimizing floor space usage. From delicate, detailed welding to secure joints, this desktop Compact laser can be used across all areas of application.

The compact design, small footprint, and movable pulleys allow the working condition of the ComWelder B1 laser machine to be more flexible and precise.

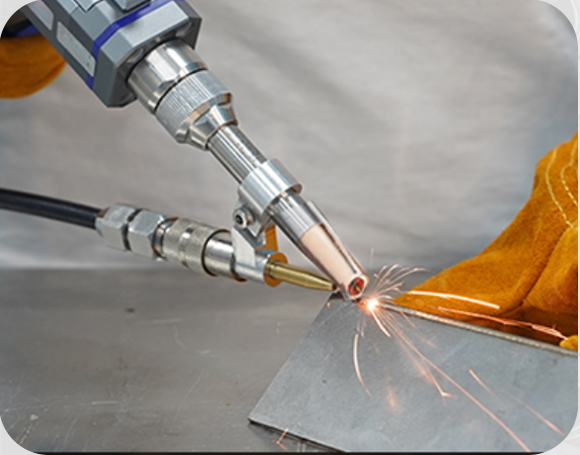

This portable fiber laser device is way more accessible than ever. Like TIG and MIG welding operators, the facilitator uses a “gun” to trigger and direct the laser beam. This makes the machine highly convenient so that even novice, inexperienced, or new welders can get a hold of it, and they can be productive and create high-quality welds, as the learning curve is much lower.

The lightweight machine, measuring 38kg in total, perfectly suits the situation when taking the machine into tight or constricted spaces. It can be transported easily from one job site to another, giving it a competitive advantage over stationary welding systems. This becomes a viable machine for welders who travel to different workstations.

Apart from being power-efficient and cost-effective, this small-size ComWelder B1 welder allows easy maneuverability, especially if you’ll be working on complex or large-scale projects. The comfortable grips and adjustable controls enhance user experience and reduce fatigue during prolonged welding tasks.

3. Quiet Operation, Creating a Quiet Working Environment

The laser adopts water-cooled heat dissipation, offering many advantages such as high electro-optical conversion efficiency, low energy consumption, compact structure, adjustment-free maintenance, and easy customer integration.

The fantastic feature of the ComWelder B1 welding machine is inverter technology variable-speed fans. These fans are a real game changer that adjusts the speed based on the actual cooling needs of the welding machine.

When light-duty welding is operating, or the machine is in the standby position, these fans run at a lower speed, which produces less noise.

When the welding machine operates under heavy loads and generates more heat, the fans can increase their speed to maintain proper cooling. This dynamic fan speed control helps minimize unnecessary noise.

4. Humanized Maintenance

ComWelder B1 laser welder features a removable welding head with manual controls to allow you to modify the laser diameter and power output in real-time. This ability will facilitate adjusting the laser depending on precise needs, resulting in a welding head well-suited for in-field metal repairs where space and time are constrained.

The primary applications of this welding head are to do in-field welding and brazing of damaged specialized equipment. The laser technology is a variable-power, continuous-wave, handheld fiber laser head for fusing metals with increased precision and maneuverability.

5. Durable And Cost-Effective

The 800w B1 hand-held laser welding machine provides high working speeds and perfect weld quality. It is used for joining metals with a 4mm thickness. The machine can weld carbon low-alloy, high-tension stainless steel, aluminum, brass, and various dissimilar materials.

The B1 high-quality laser processes and cost-effective manufacturing require minimal consumables. Unlike traditional TIG welders, fiber handheld laser welders can increase speed by up to 4 times.

Consequently, the output is substantial, and the welding turns out very strong, making it possible to perform a variety of techniques, including thermal conductivity welding, continuous deep penetration welding, spot welding, butt welding, overlap welding, seal welding, seam welding, and many more.

The safety design and user-friendly features protect the operator to the greatest extent. It’s easier to handle, has consistent and high-quality output across various materials and thicknesses, and minimizes heat-affected zones to ensure durability and aesthetics.

The well-known durable features of B1 fiber laser welders are evident from their 800W power consumption, low noise, no special temperature conditions, welding dissimilar metals, and high melting point metals. The handheld laser welding machine adopts an integrated design, is small in size, and is suitable for various working environments.

Different types of welding joints are available: butt joint, lap joint, tee joint, edge joint, and corner joint. The main consumables are working gas (nitrogen & and argon), nozzles, and protection mirrors. Thanks to the 5m gun cable, welding can be carried out considerably from the machine.

- Stable and Reliable Performance

Lasers’ ability to focus at a micro level makes them phenomenal. Laser welding can target a spot as small as 0.2 mm.

The ComWelder B1, targeting a 1070±10nm wavelength, is shorter than CO2 lasers. This means that this welder has enhanced laser absorption that can lead to deeper weld penetration, especially in reflective materials like aluminum and mild steel.

Moreover, fiber laser welders have better beam quality than YAG lasers. Fiber laser welding combines the benefits of CO2 and YAG lasers and gives better performance.

Material thickness is also not an issue, as laser welding can easily create deep keyhole penetration for clean welding seams. Moreover, fiber lasers can achieve a welding speed of 16 mm/s (and higher) with ease which was difficult in the past.

7. Advanced Swing Function

The in-built oscillation (the side-to-side rapid movement of the electrode in a dot, straight mode) mechanism in ComWelder B1 weaves the welding arc through the Left / Right direction as an oscillatory movement over the weld surface.

The B1 Welding oscillators control the laser head with the back-and-forth movement to reduce the number and layers of the weld by controlling oscillating speed, width, and pause time. Then, minimize welding defects for perfect welding seam.

This B1 welder will do the trick for you if you’re looking for better and more accurate work.

This highly regulated oscillatory movement of an arc ensures the controlled spread of Arc Heat over the weld surface, resulting in a uniform, smooth, precise, and stable flow of weld globules.

The Controlled & and regulated spread of Arc heat provides a distinctive advantage of excellent penetration at maximum Heat Utility efficiency. This also ensures reduction in the Affected Zone, High welded metal deposit efficiency and highly uniform fused beads.

Since the advanced swing function controls the heat input, the spatter from the weld is significantly reduced.

This means you’re at peace of mind from worrying about too much spatter on the surface. This also reduces the chances of chemical reactions that can cause danger to the welder.

Comparison of ComWelder B1 with Traditional Welding Machines

Handheld fiber laser welding outperforms in many areas with its unparalleled superiority in welding accuracy, efficiency, reliability, speed, high depth, and small deformation. Below are the reasons that set B1 apart from traditional welding devices.

- The welding equipment of the ComWelder B1 is easy, simple, and most effective. The laser beam does not drift through the electromagnetic field. The laser welding head facilitates the process even smoother and more intricate.

- The B1 Fiber laser technology generates very little heat at the weld point, allowing users to easily weld 0,05mm (.002”) away from the most complicated and intricate parts without damaging heat-sensitive materials.

- B1 Fiber laser welding is gas efficient and easier to operate than MIG & MAG, so much so that it hardly takes 15 minutes to train a new employee.

- In contrast to the traditional welding methods, the current main consumables for fiber laser welding are the amount of electricity and the shielding gas and wire-like, which are less than the MIG & MAG

- The B1 handheld laser welding machine can create strong seams even at room temperature, improving traditional techniques. The weld carried under B1 is narrow, with an excellent depth-to-width ratio and higher strength.

- It can perform micro-welding. The laser beam can obtain a small spot after focusing and be accurately positioned, which can be applied to the assembly welding of micro and small workpieces for mass production automation.

- Despite costing a higher initial tool investment, laser welding can often prove more cost-effective than traditional welding due to its faster processing speed. Rapid production speeds also mean greater production capacities, resulting in quicker turnaround.

- It can weld hard-to-reach areas and perform non-contact long-distance welding, which has excellent flexibility. During welding operations, the laser melt localizes areas of the workpiece and, if present, the filler material to form precise welds.

- It is a more environmental-friendly option with minimum fumes and welding emissions.

| Item | B1 Laser welding | Arc welding | Brazing | Resistance welding |

| Average welding speed(m/min) | 4 | 0.7 | 3-4 | 5 |

| Welding shape variable | Small | More | Less | Normal |

| Welding accuracy | High | Normal | Normal | Normal |

| Welding slag adhesion | Very few | Very few | Very few | Very few |

| Consumables consumption | Less | More | Less | More |

| Price | Normal | Normal | Low | Low |

Conclusion

As demand for higher precision and speed, better welding quality, and the ability to weld a broader range of materials, Fiber laser welding, such as ComWelder B1 handheld welder is the next best thing that is increasingly been used in today’s production lines.

Fiber laser welders ensure many benefits over traditional welding methods.

The list includes environmentally friendly processes, reduced emissions and waste, and less maintenance needs than other welding methods. This makes it a cost-effective and sustainable solution for modern manufacturing