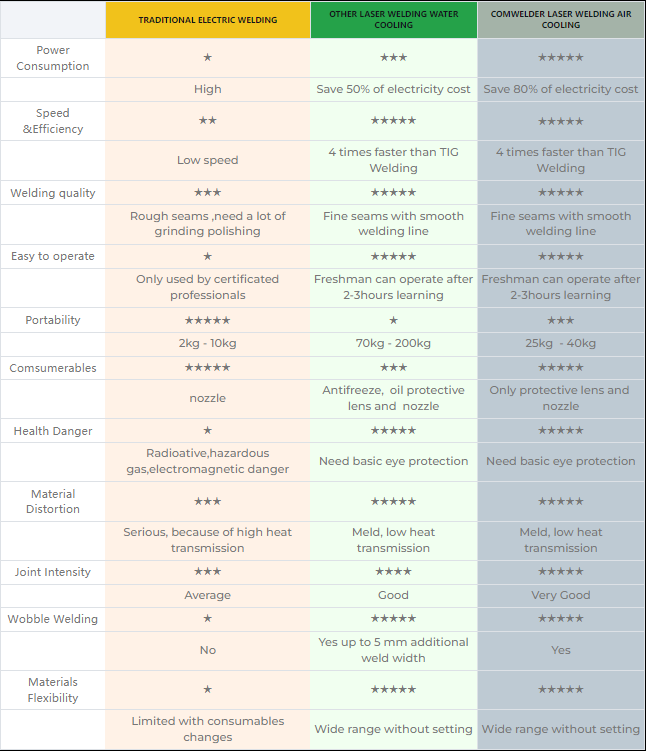

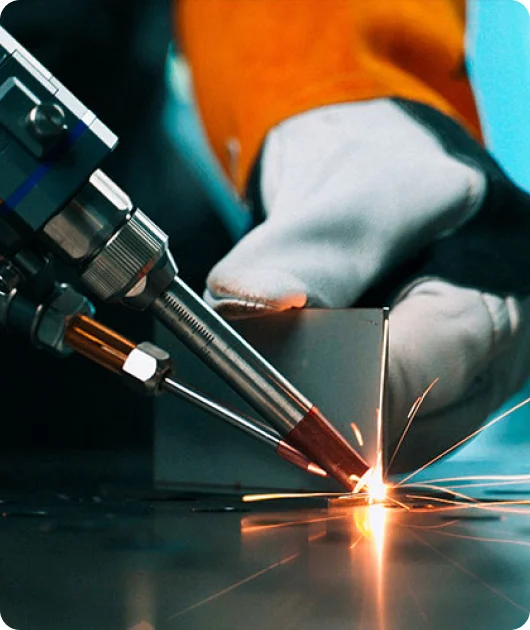

Comwelder Handheld laser welders are portable fiber laser delivery machines capable of welding various metal materials within seconds. They comprise a main unit that houses the laser source and amplifier, connected to a handheld gun-like unit called the laser welding head.

Comwelder Handheld laser welding machines are compact and roughly the size of a desktop PC. Almost all commercially available machines come with wheels at the bottom of the machine for more effortless mobility.

The handheld unit is considerably more lightweight than traditional welding methods, providing operators with a high degree of freedom and control when welding.

Additionally, the exit nozzle on the gun is interchangeable, further adding to the flexibility provided by the machine. Nozzle shapes direct the laser beam and ensure only the desired part gets welded.

Comwelder Handheld laser welding machines are compatible with several metals, including titanium and stainless steel. Research has also shown that fiber laser welding is compatible with rare metals like Vanadium, Tantalum, and tougher Stainless Steel Alloys.

5 Major Benefits of Handheld Laser Welders

Handheld laser welding offers all the benefits of fiber lasers and more. Here are some of the many benefits of a handheld laser welding machine.

1 – No Filler Metal Required

Traditional MIG/TIG welding equipment necessitates using a filler metal rod. As the metal is heated, the filler metal melts between the two surfaces and bonds them together.

Laser welding doesn’t need a filler metal, as it selectively melts two metal surfaces together. The lack of filler metal reduces the operator’s welding complexity and the overhead costs of buying and storing filler metal rods.

A handheld laser welding machine is a one-stop solution compared to the complex and cumbersome MIG welding.

For wider gaps between metal surfaces (>0.2mm), a filler metal is also required for laser welding machines.

2 – Cleaner Welds

Laser welding provides a nice and clean weld finish that is otherwise impossible with traditional welding methods.

Traditional means of metal welding (TIG/MIG/Arc Welding) result in a strong weld with an undesirable weld bead. The extra mass of the filler metal ends up as a thick line on the final product.

Post-processing equipment becomes necessary to clean up these welds. Laser welding forgoes all this by making a clean weld in the first place, saving you time and money in the post-processing stage.

3 – Less Heat Input

Laser welding is a highly efficient process, utilizing a fraction of the energy of traditional methods while delivering the same quality results.

Laser welding equipment is designed for pinpoint heat input. Therefore, the laser welding machine can avoid a lower energy deposit.

Less energy input into the metal materials means negligible post-weld warping.

4 – Finer Welding Control

A good and robust weld requires an experienced operator and quality welding equipment. Studies have shown poor welding control can lead to larger weld pools, resulting in welding defects.

Experienced welders can compensate for the instability in the welding equipment, but the solution is never perfect. A handheld laser welding machine is lighter and more flexible, allowing welders to hone their skills further.

An experienced welder can match the quality and precision of an entry-level welding robot. Additionally, laser welding is more forgiving to novices and minimizes chances of operator error. You can learn about ways to improve welding control in this process.

5 – Wider Material Compatibility

Laser welding is quite versatile when it comes to material compatibility. It can weld all the usual metals and even some uncommon other metal materials like volatile magnesium, unstable vanadium, and tough titanium.

Additionally, due to its low heat input, it can easily weld thin materials. One big problem in welding thin materials is that traditional arc welding deforms thin materials.

You can even weld some thermoset plastics using a handheld laser welding machine.

A standard laser welding machine is compatible with the following materials and their alloys.

- Steel (High Carbon & Galvanized)

- Stainless Steel

- Copper

- Aluminum

- Magnesium

- Titanium

- Nickel

- Plastics

- etc.

Factors to Consider When Buying a Handheld Laser Welder

Handheld laser welding machines have gotten so good over the past few years that you shouldn’t have any problems buying a capable welding machine from a reputable seller.

However, buyers should be well informed of the most important factors that contribute to laser welding machines’ performance.

Power and Performance

Laser welding machines shouldn’t be judged on their laser power alone. Due to the laser beam’s higher power density, a 800W-2000W laser is more than enough for most metals.

Consider a handheld laser welding machine’s advertised continuous and peak power. Most lasers will only operate at their peak output for a few seconds. A 2500W peak power laser welder will revert to ~1500W afterward.

Portability and Design

Portability is a big selling point for laser welding equipment. Large projects mandate that the welder be moved around to accommodate the workpiece.

Choose a laser welder that can be easily moved around and is not too bulky or heavy. Next, you want a design with no protruding parts that can be easily damaged in transit.

Ease of Use

A laser welding machine should be treated as any other tool. It shouldn’t require a complex and tedious instruction manual to operate.

Choose a welding machine that comes with simple and intuitive controls.

How Handheld Laser Welders Compare to Other Welding Machines

Laser welding is a newer technology compared to traditional welding methods. It still has a long way to go, but it already shows several benefits over its older brethren.

Handheld Laser Welders vs. TIG/MIG Welders

MIG/TIG welding is a decent all-rounder metal joining solution. However, this process is challenging to automate and lacks laser precision.

TIG welding generates more heat, requires filler material, and produces a less desirable finish.

However, it is a low-cost solution and has a short learning curve. Studies also show that the tensile strength of TIG-welded metals is slightly higher than laser-welded ones.

Handheld Laser Welders vs. CO2 Welders

Gas welding equipment is bulky, unreliable, and obsolete. It lacks fine-tune precision, is very inefficient, and has a fragile gas chamber made of glass.

Fiber lasers have a lifespan of 20,000 hours compared to the 2,000 hours of CO2 lasers. On long, complex welding projects, you run the risk of a failing CO2 gas chamber. The industrial sector doesn’t have two thousand hours of machine operation time.

The only saving grace for CO2 welding is its dirt-cheap pricing and broader availability.

Safety Tips for Using Handheld Laser Welder

Before we wrap up this article, let’s review some basic safety guidelines for handheld laser welding.

Proper Storage

Laser welding machines are sensitive devices; moisture and dust ingress can hamper performance and damage internal components.

Additionally, on the factory floor, ensure that small metal chips and debris don’t enter the laser welding machine.

Cable Management

The optical fiber cable connecting the weld gun to the laser system is fragile. Bending at sharp angles or running over one will damage it beyond repair.

Hand & Eye Protection

Always wear proper hand and eye protection. Safety goggles and fire-resistant gloves are your friends.

Conclusion

Laser welding has slowly grown over the years, starting from CO2-based lasers and then shifting to optic fibers. Their compact size has paved the way for handheld laser welding machines that are just as capable as traditional methods. Additional benefits of laser welding include higher quality weld finish and excellent energy efficiency.

All top laser welders offer 800-2500W of power and come with changeable welding heads (nozzles). Thus, buyers should focus more on ease of use and portability when getting a laser welder.

In the fast-evolving world of welding technology, handheld laser welders have become one of the most convenient and reliable solutions. Whether you are a professional welder seeking the perfect tool for your trade or a DIY enthusiast looking to take your projects to the next level, there is a handheld laser welding machine that’s perfect for you.

One thought on “What is a Handheld Laser Welder?”