Handheld laser welding system is highly accurate and precise compared to the traditional laser welding machine and other welding systems such as TIG and MIG welding. However, even though the laser welder has advantages over conventional methods, it also has disadvantages. Hence, getting to know the two welding processes, as depicted in this article, can help make the right decision.

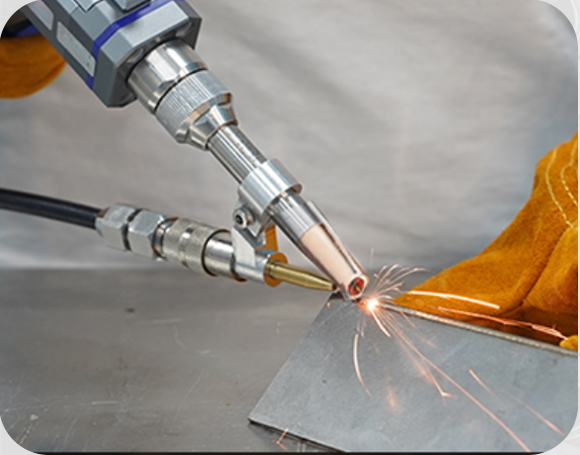

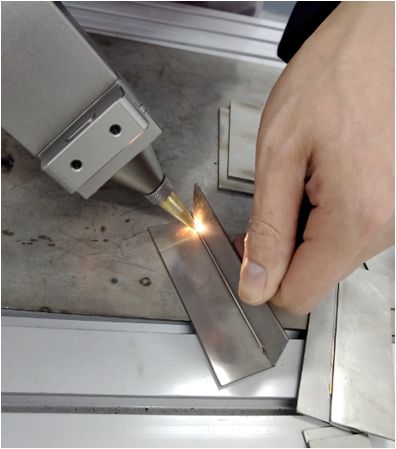

How Does a Handheld Laser Welder Work?

Handheld laser welding machines uses generated laser beam to melt and join two materials. The laser source can be fiber or solid-state, and it determines the welding speed and rate.

These machines are versatile and compatible with different material types and of different complexity in terms of design. They can melt and join thin and thick materials with accuracy making them suitable for welding small parts that require minimal distortion because the heat source is focused on a particular area.

Handheld Laser Welding Machine: Pros and Cons

A handheld laser welding machine can create strong seams even at room temperature. This machine is an improvement to traditional techniques. Below are the pro and cons of the machine.

· Portability

It has a small size and is highly lightweight. As a result, this makes it useful for onsite and offsite operations. With it, you can accurately weld parts with complex designs or large parts.

· Versatility

It is compatible with many material types. Additionally, it is suitable for both different and similar materials. However, for dissimilar materials, there is a need to check for material compatibility using their chemical and physical properties.

· Welding Speed

Laser welding system generally has a fast welding speed due to the highly concentrated heat source. As a result, they are the better choice for production efficiency.

· Heat Input

Compared to other methods, the handheld laser welder’s low heat input makes them ideal for joining thin, delicate parts. Other methods can lead to charring and dimensional inaccuracy.

Handheld laser welders also have their shortcomings, including the following:

· Initial Investment

The cost of running a handheld laser system is quite high. In addition to the initial investment, the maintenance fee and labor cost contribute to the overall expenses associated with this machine.

· Power Output

Compared to other methods, handheld laser welders have a relatively low power output which can be an advantage but offers disadvantages in terms of welding efficiency.

What Are the Common Traditional Welding Techniques and How Do They Work?

Below are the conventional welding techniques and how they work:

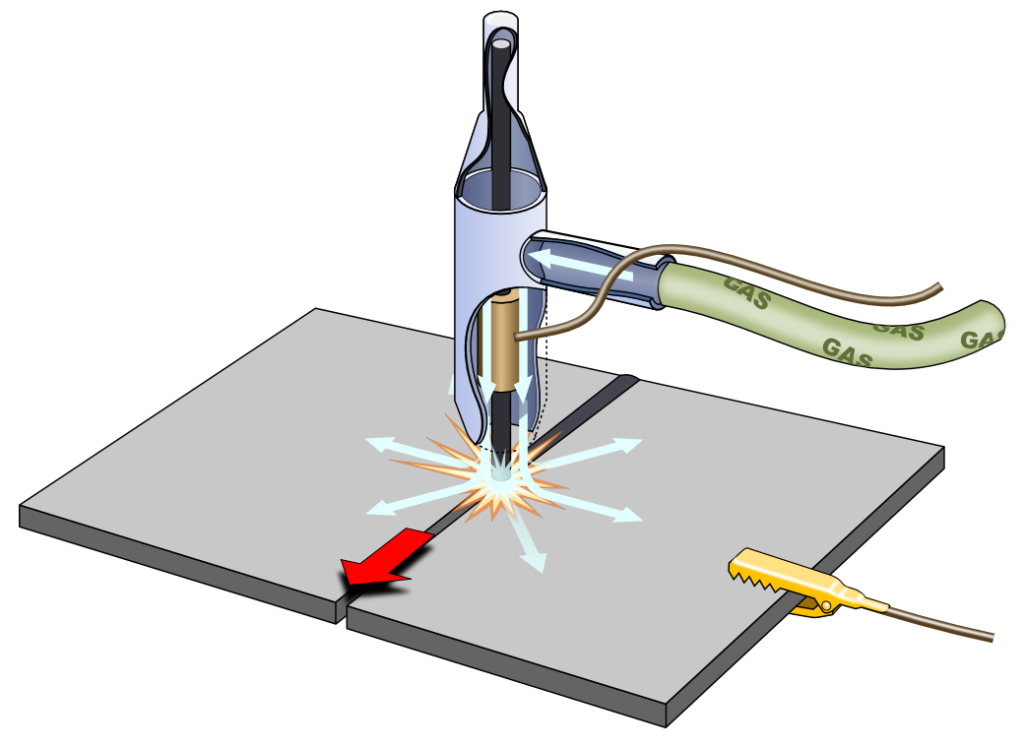

· Metal Inert Gas Welding (MIG)

This welding technique welds two materials by melting a filler into the welding joint created by the adjoining piece. The direct current (power source) creates an arc, hence the welding technique’s name.

Typically, a direct current is the power source that provides the electrical energy which melts the filler material while creating an electric arc into the workpiece. On cooling, this joins the two materials.

Concurrently, an inert gas, usually argon and helium, travels through the welding head. These gases shield the weld zones from atmospheric contamination. Its efficiency and creation of uniform and clean seams make it suitable for welding parts in industries that deal with manufacturing and fabrication.

· Tungsten Inert Gas Welding (TIG)

TIG welding uses a tungsten electrode as a filler material. The filler material is unique such that it does not melt. It only supplies the heat which melts the workpiece and joins them on cooling.

TIG welding also uses shielding gas such as helium and argon. Furthermore, the created welded joint is strong. As a result, they are suitable for joining structural parts.

· Shielded Metal Arc Welding (SMAW)

This welding technique uses a flux pre-coated electrode to form the electric arc. Like MIG welding, the electrode melts the material surface while acting as a filler material, forming a weld pool. Also, the flux coatings on melting improve weld quality by eliminating the need for external shielding gas, leaving joints of high mechanical strength. The type of electrode and flux composition varies. The base material property and welding parameters affect the selection process.

· Oxyacetylene Welding (OAW)

Oxyacetylene welding uses oxygen and acetylene gases to join metals together. Acetylene gas, a combination of carbon and hydrogen, is a fuel gas. In the presence of oxygen, acetylene gas burns and produces a high-temperature flame that is hot enough to melt most metals. With the right ratio of both gases, oxyacetylene provides a flexible and efficient welding operation.

Furthermore, the oxyacetylene welding process is primarily for metals with a high melting point. However, it can also be optimized for non-metallic materials, including thermoplastics and glass. It is important to note to control the temperature as extreme heat may damage the material’s structure.

Traditional Welding Techniques: Advantages and Disadvantages

Consider TIG, MIG, and other traditional welding techniques for the following reasons:

· Operating Cost

Many of the above traditional processes are cost-effective options. The cost of operating them is low and does not significantly affect a company’s finances. The machines are affordable and do not require heavy investment to train the operators. Additionally, they are accessible and readily available for many businesses.

· Weld Strength

These processes can create more durable welds. The heat generated by the welding arc gets transferred to the base material quickly. This creates a strong bond that can withstand stress and vibrations.

· Versatility

Most conventional welding methods are versatile as they can produce temporary and permanent welds on metals, thermoplastics and glass.

· Material Thickness

The total heat input is high, which makes them suitable for thick materials.

Conventional welding has some shortcomings, which include:

· Part Deformation

Most of these conventional methods are associated with an unintended heat transfer to the surrounding material. This high heat-affected zone area deforms thin materials and parts.

· Welding Rate

The arc welding method is time-consuming. It requires multiple passes to complete a single welding operation. Additionally, most welds require post-welding grinding to remove surface irregularities.

Handheld Laser Welding Vs Traditional Welding

Let’s compare both welding operations!

· Cost and Ease of Use

Handheld laser welding machines come with a relatively high investment. Additionally, the servicing and maintenance fees are also considerably more compared to the traditional methods.

Regarding ease of use, traditional methods require technical expertise, which can increase operating costs. Furthermore, handheld laser welders have easier to use. Some models even feature automation which increases operational use.

· Speed and Production Efficiency

With a faster heating and cooling rate, handheld laser welders are better than traditional methods. As a result, they are more efficient and productive in terms of small-scale welding. However, in large-scale welding, traditional methods are more suitable due to the higher long life compared to laser welders.

· Heat Affected Zone (HAZ)

The area around the weld joint that experiences an appreciable temperature increase also differentiates the different welding processes. The HAZ is smaller because laser welding is a contactless process that uses a focused laser beam.

On the other hand, the heat from most traditional welding techniques affects the surrounding material extensively. This can change the microstructure of the metals through recrystallization, phase transformations and precipitation. Furthermore, the area of the heat-affected zone differs among conventional welding methods. The HAZ mig welding produces comparatively larger because it has a high heat input.

· Precision and Control

The control level in laser welders depends on the level of automation. Nevertheless, the operator has total control. This is better than traditional welding techniques, which have lesser precision, no automation, and require high control and focus.

Furthermore, the accuracy and precision of the final weld made with traditional methods may be lower. However, using a highly skilled operator can overcome this shortcoming. By overseeing the process, the consistency of the final weld may be similar to laser welds.

· Material Compatibility

Laser welding has wide material compatibility, although it is more suitable for thin parts. The smaller heat-affected zone they produce makes them the method of choice for delicate and heat-sensitive materials.

On the other hand, the material compatibility of traditional techniques depends on the method used. Most are strictly for joining metals and may be less effective for non-metallic materials. However, traditional welding techniques are better for very thick parts because of their high heat input.

· Applications

Though one uses different welding methods for manufacturing and repair operations, their application in industries differs. Handheld laser welders are more suitable for small-scale welding and materials with thin, delicate, or complex designs.

However, traditional methods, especially MiG welding, are more suitable for chassis and frames. Furthermore, arc welding has limited use in the electronics industry because it can damage electric components irreversibly.

Conclusion

Handheld laser welding machines are becoming popular in several part manufacturing industry. They have some advantages and disadvantages over traditional welding techniques. Hence, they have variable applications. This article compared both welding systems, to inform you on choosing the right one for your project. If you have any questions, please contact us concerning the different welding methods.