At present, argon arc welding still occupies the mainstream in welding thin plates. For example, customers in the door and window industry use argon arc welding which is simple and convenient. However, argon arc welding has low welding efficiency and requires welder skills. Many customers, especially those with thin plates, have relatively scarce welding skills and high technical requirements, which has led to an increase in enterprise labor costs. If you encounter a welder with poor skills, the product will be scrapped.

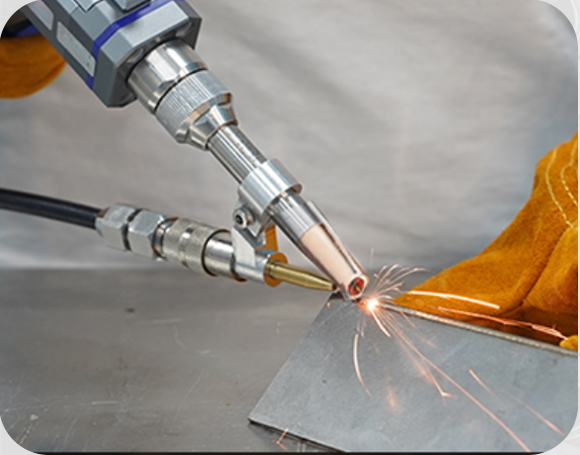

As laser handheld welding products continue to mature, the advantages of handheld laser welding are more obvious. Laser welding efficiency is high, and the welding speed is several times that of argon arc welding. At the same time, the welding quality is high and the deformation is small. The most important thing is the technical level of the operator. The requirements are not high, especially in the sheet metal industry. You can get started with air-cooled laser welding through short-term training. The technical requirements are lower, which is more conducive to reducing the cost of recruiting and employing people.

Handheld laser welding is a new welding method that has emerged in recent years. It is easy to use, efficient in workmanship, and has beautiful welds. It can realize various processes such as electric welding, butt welding, and sealing welding. With an intelligent control system, precise welding control can be easily achieved. At present, handheld laser welding has been widely used in many industries such as kitchen and bathroom, home appliances, furniture, doors and windows, advertising, etc. The wave of intelligent manufacturing is unstoppable.

After the introduction of air-cooled laser handheld welding machines, welding equipment has become more abundant. Comwelder laser relies on the advantages of the Comwelder brand. Comwelder laser is in the first echelon in China. Comwelder chooses to cooperate with larger manufacturers. Product sales are only the first step, and after-sales service is guaranteed. It is also very important to choose a big brand, which means more reliability and peace of mind.

Talking about the potential for the future development of laser handheld welding, Comwelder believes that laser welding has several core advantages: maintenance-free, lightweight and portable, and reducing operator fatigue. In the future, laser handheld welding will become an increasingly important welding tool in the market.

Laser processing and manufacturing have experienced rapid development in the past decade. One of the important factors driving market growth is the replacement of traditional technology with lasers.

From previous methods such as silk screen printing and knife engraving, we have transitioned to laser marking and engraving. Similarly, we have moved from punch and blade cutting to laser cutting, and from chemical agents and pickling to laser cleaning. All of these are significant changes in technology.

The use of lasers has not only brought technological progress but has also aligned with the trend of industrial technology development towards environmental protection and green manufacturing. By making processes more efficient, increasing output, and improving the aesthetic appeal of products, we can achieve a more sustainable future.

Many of the traditional grinding wheel cutting have been replaced by laser cutting

Rapid rise of handheld laser welding

In terms of welding, there has been a shift in the process from traditional electric and arc welding to laser welding, which is currently the most important application for metal materials.

Although laser welding has been in development in China for nearly 30 years, the previous low-power YAG laser welding machines were typically single machines, with low degrees of automation, manual loading and unloading, low power, small worktable formats, and difficulties in operating on large parts, which hindered the spread of laser welding applications.

In recent years, laser welding has made significant progress, particularly with the application of fiber and semiconductor lasers. There have also been developments in workpiece fixtures, automatic control, and automatic loading and unloading.

Nowadays, high-end automatic laser brazing systems have been equipped in some automobile factories, and it is also used in aviation parts, the locomotive body of CRRC, and other industries.

Furthermore, power battery laser welding for new energy vehicles has become a crucial application of laser welding.

All of these examples illustrate the high-end applications of laser welding.

By the end of 2018, handheld laser welding began to gain popularity due to the significant decrease in the cost of fiber lasers and the advancement of fiber transmission and handheld welding joint technology.

The unexpected rise in demand for handheld laser welding led many manufacturers to start producing these machines in 2019. It is estimated that hundreds of enterprises are now producing handheld laser welding machines.

One reason for the rapid popularity of handheld laser welding is its convenience and ease of use. Compared to high-end automatic laser welding, which requires advanced technical knowledge and expertise, handheld laser welding has a lower technical threshold and can be operated manually without the need for fixtures or motion control. Workpiece alignment and alignment clamping are done by hand.

While some may view this as a regression from automation to manual operation, it is important to consider the actual application cost and acceptance. Overall, handheld laser welding has proven to be a practical and accessible alternative to high-end laser welding for many manufacturers.

Taking stainless steel welding as an example, there are currently a wide variety of welding processes available, but the most common ones are ordinary argon arc welding and spot welding. Despite years of development, manual welding operations are still widely used, and there are many such welders in the industry.

Argon arc welding is a popular choice for welding kitchenware, kitchen supplies, bathroom hardware, stainless steel doors and windows, anti-theft nets, stainless steel furniture, hotel decoration, and other industries that use a significant amount of stainless steel.

In terms of welding nature, manual welding is considered a traditional low-end welding process, typically used for thinner stainless steel sheets and pipes. Nowadays, electric arc welding has been replaced by laser welding, which operates similarly to electric arc welding. Hand-held laser welding can be performed by ordinary welders with less than half a day’s training, making it a high-potential replacement for traditional argon arc welding.

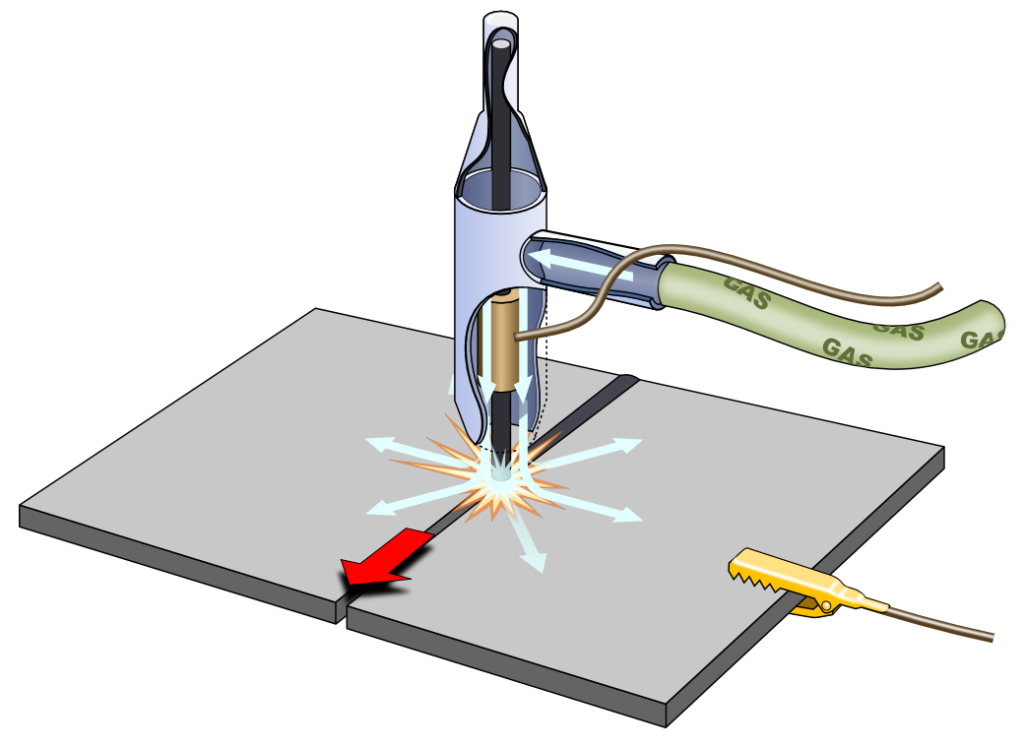

Conventional argon arc welding operation

It is a trend that laser welding replaces argon arc welding.

Argon arc welding typically requires welding wire to be melted and joined, resulting in a protruding welding interface. In contrast, laser welding doesn’t need welding wire, resulting in a relatively smooth interface.

Argon arc welding has been developed over many years and is the most widely used welding process. Laser welding, on the other hand, is a newer process that is rapidly developing, but still represents only a small part of the total welding industry.

It is an inevitable trend for laser welding to replace some of the argon arc welding applications.

Currently, argon arc welding is still very popular due to its low cost of use.

A welding machine for argon arc welding can be purchased for thousands of yuan, with some cheaper models costing only around 2,000 yuan. In addition, supporting products such as small welding guns, welding wire, and argon are priced at less than 1,000 yuan, with the cost of a complete set being approximately 3,000 yuan.

In early 2019, hand-held laser welding equipment cost more than 150,000 yuan per unit. However, with increased competition, there are now many manufacturers of hand-held welding equipment, and 1 kW models can be purchased for around 60,000 yuan.

Handheld laser welding is faster

Argon arc welding only selects fixed positions at the corners of the material for spot welding in order to save labor and materials, while laser welding utilizes zipper welding along the seam.

Compared to argon arc welding, laser welding provides better firmness.

Handheld laser welding equipment with power segments of 500 watts, 1000 watts, 1500 watts, or even 2000 watts is commonly used for welding thin plates and steel sheets.

Nowadays, handheld laser welding equipment is becoming more compact, including necessary chillers that can be integrated into the whole chassis to achieve integration. This equipment has good mobility and much lower procurement costs than before.

It can meet the requirements of a large number of metal processing stores and processing plants and can even be taken to the construction site for on-site operation.