If you want a high-quality weld, try hybrid laser welding. Discover hybrid laser welding and create precise welds on various materials.

Welding is a vast technique to join various materials. This technique encompasses multiple types, including electron-beam, laser, arc, and gas welding. In addition to these types, hybrid laser welding has been developed that combines the strengths of laser and arc welding.

In this blog post, you’ll explore hybrid laser welding and its application. You’ll also learn the differences between hybrid laser welding and traditional welding techniques. So, let’s get into it.

What is Hybrid Laser Welding?

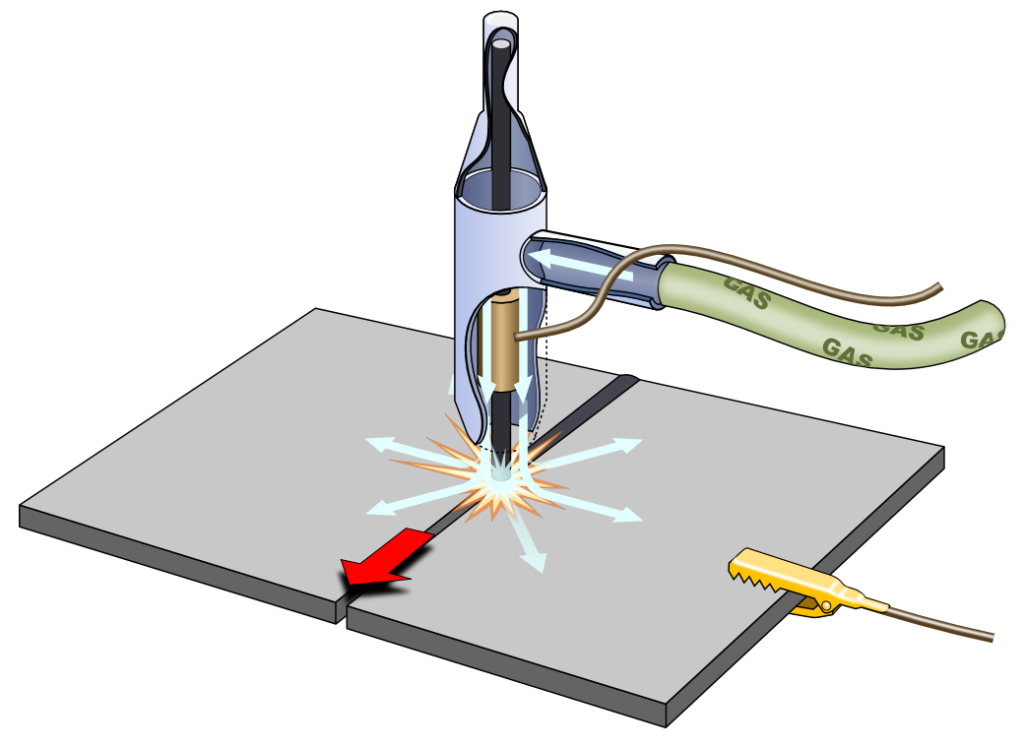

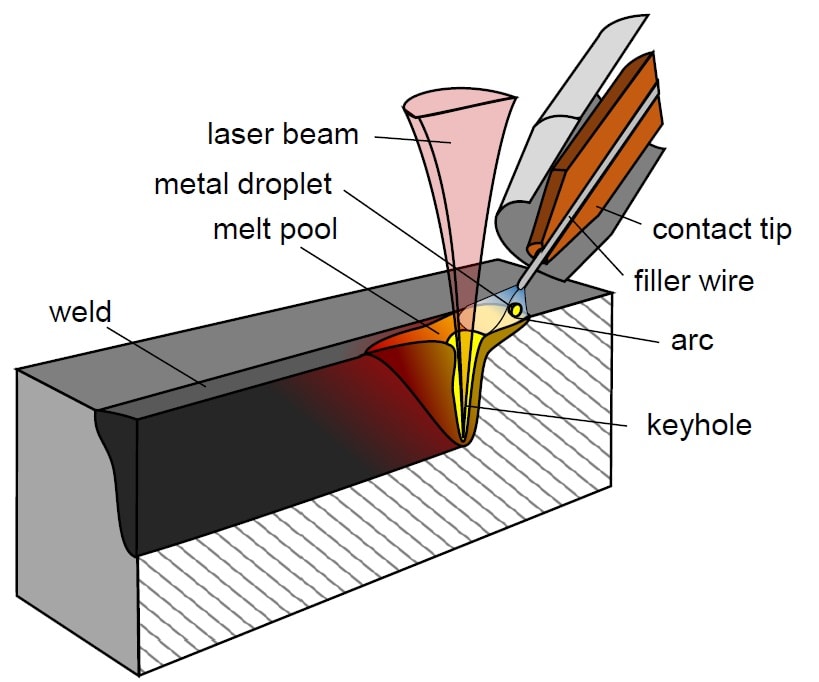

Hybrid laser welding is a unique type of welding that utilizes laser and arc welding. Initially, a laser machine generates a focused, high-intensity laser beam. As the laser beam hits the surface of workpieces, it vaporizes the material, creating a vapor cavity. The vapor cavity is called a keyhole. It facilitates deep penetration of the weld.

The energy-flow density of arc welding creates a wide focal point. Arc welding provides additional heat and filler material for improving the weld quality. According to ResearchGate, arc welding acts as a secondary heat source in hybrid laser welding.

Laser and arc welding simultaneously strengthens the welding zone and boosts the welding process. Combining laser welding with the traditional arc welding method helps welders overcome the limitations of each technique. Moreover, it also offers better welding speed than other welding techniques.

Types of Hybrid Laser Welding

Hybrid laser welding has several types depending on the arc welding you employ. The following are common types of hybrid laser welding:

1. Laser-MIG Welding

According to ScienceDirect, hybrid laser welding combines laser welding with metal inert gas (MIG) welding techniques. The high-energy laser beam creates a heat source that contributes to producing deep weld.

MIG welding is a type of gas metal arc welding (GMAW) that simultaneously generates an electric arc between the workpiece and the wire electrode. It provides filler material for the welding process and improves the weld by reducing the chances of porosity. The release of shielding gas also contributes to preventing the weld from potential contaminants.

2. Laser-Plasma Arc Welding

This hybrid laser welding involves the integration of plasma arc with laser welding. Plasma arc generates high-energy welding arc by utilizing ionized gas. The high-energy plasma heats the workpiece, enabling the laser beam to penetrate the material.

The plasma arc in this hybrid welding offers better control over the heat input and improves weld pool stability. This technique is effective for welding thin plates and dissimilar materials that need controlled heat input.

3. Laser-MAG Welding

This technique involves the integration of laser welding with metal-active gas (MAG) welding. Like MIG welding, it also generates an electric arc using a wire electrode and workpiece. However, MAG welding involves active shielding gases.

According to TWI, MAG employs a mixture of carbon, oxygen, and argon. The use of active shielding gas helps to prevent contamination by removing oxides during the welding process. Laser welding produces intense laser beams to produce high input energy, resulting in the creation of deep welds. The combination of laser and MAG enables an efficient, deep-penetrating weld with minimal heat input.

4. Laser-TIG Welding

This hybrid welding integrates the tungsten inert gas (TIG) welding technique with the laser welding method. According to Wikipedia, TIG welding employs a tungsten electrode. The welding process doesn’t consume the tungsten. Instead, a filler material is used to complete the welding.

An inert shielding gas protects the weld from contaminants and oxidation. Generally, helium or argon is used as an inert gas. The combination of laser with TIG helps you enhance welding speed, boosting your productivity. This hybrid welding also improves joint quality, making it suitable for industries that demand high-end welds.

Process Advantages of Laser Hybrid Welding

Hybrid welding is a beneficial process, employing the features of arc and laser welding. It also enables you to overcome the limitations of both types of welding, contributing to improving the end product. Here are some advantages of laser hybrid welding:

1. Boost Welding Speed

Hybrid welding integrates the benefits of both laser welding and traditional welding methods and boosts welding speed. The laser machine generates a high-energy, intense laser beam as a heat source to vaporize the material instantly. Arc welding requires additional heat input, improving the fusion and deposition rate.

The hybrid process produces quicker and stronger welds. It improves the overall production rate of the welding process, making it an efficient process for high-volume production.

2. Boost Tolerance

Joint gap is a crucial aspect of welding processes, affecting the quality of welded joints. Joint gaps often deteriorate your weld, leading to defects and joint failures.

Employing hybrid welding allows you to improve tolerance to joint gaps. The combination of the heat input of the laser beam with the heat of arc welding allows you to prevent deviations in joint configurations during welding.

Hybrid welding offers you better welds that have 2 to 3 times more tolerance than laser welding. The improved tolerance of hybrid laser arc welding minimizes post-welding distortions, making it a versatile choice for industries that require greater precision.

3. Increased Single Pass Penetration Depth

Hybrid laser-arc welding also enables you to achieve increased single-pass penetration depths. The intense and focused energy from the laser beam facilitates deep penetration into the material.

The laser beam, along with arc welding, allows deeper penetration of the joint. The high energy of two welding techniques combined creates an intense heat source that results in increased single-pass penetration depths. This feature is necessary for industries that involve the welding of thicker materials. It also contributes to strengthening the weld, making it more durable and resistant to stress.

4. Improved Weld Quality

The quality of the weld is imperative for various industries. It is also necessary to craft durable products. However, creating a quality weld is a daunting task due to the complexity of the welding process and the potential for defects.

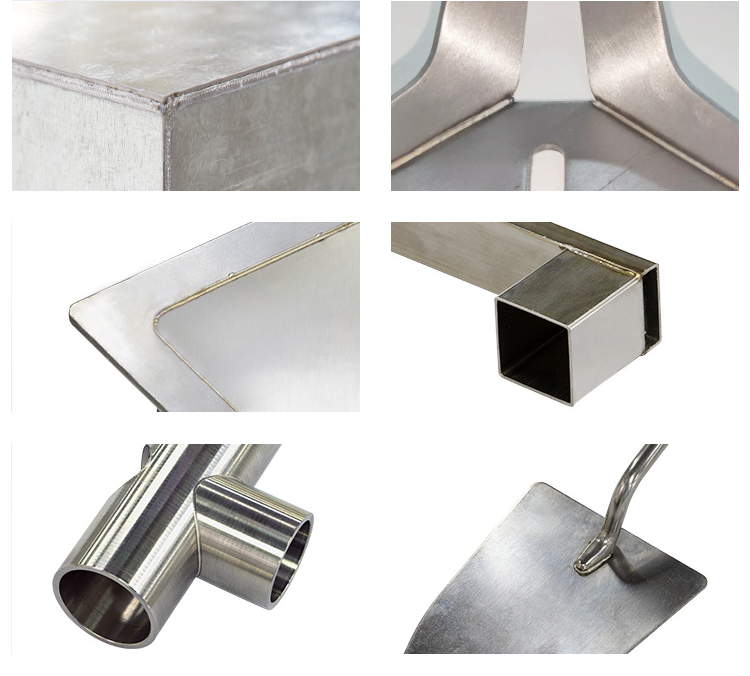

Hybrid laser welding offers a convenient way to improve the weld quality. Laser welding offers you precise control over the welding process. It offers you a narrow weld bead, allowing you to minimize the distortion. The synergistic effects of laser and arc welding techniques reduce the risks of porosity and distortion in the weld. It enables you to achieve high-quality welds with minimal defects.

How does Hybrid Laser Welding Differ From Traditional Welding Methods?

Traditional welding and hybrid laser welding have prominent differences. Here is an overview of the differences between the two welding types:

| Basis of Difference | Hybrid Laser Welding | Traditional Welding |

| Energy Source | Dual-energy source ( Laser beam and electric arc or gas flow) | Single energy source (electric arc or gas flow) |

| Joint Quality | Better joint quality | Compromised joint quality |

| Welding Speed | Higher welding speed | Slow welding speed |

| Material Thickness | Weld thin to thick materials | Weld thick materials |

Hybrid Laser Welding VS. Traditional Welding Methods

1. Energy Source

Traditional welding derives energy from a single source, like an electric arc or gas flame. This energy is often insufficient for the creation of a precise weld.

In contrast, hybrid welding has a dual energy source. The focused laser beam from a laser welding machine has a high intensity that can penetrate thicker materials. In addition, the heat energy of arc welding also contributes as a heat source. It increases the intensity of the welding process, leading to better penetration and weld quality.

2. Joint Quality

Traditional welding process often leads to deformities and defects in the weld due to insufficient penetration of the weld. It leads to poor joints with porosity and joint gaps that weaken the weld.

On the other hand, hybrid laser welding combines the advantages of both laser and arc welding techniques to achieve deep penetration and narrow weld beads. It offers you precise control over the welding process, allowing you to position the weld accurately. It results in high-quality joints with minimal defects.

3. Welding Speed

Welding speed is another significant difference between traditional and hybrid welding techniques. Traditional welding has limited welding speed due to several factors, including electrode consumption, arc stability, or gas flow. These factors limit the welding speed and lead to a low production rate.

In comparison, hybrid laser welding involves high energy from laser and arc welding. Two energy sources improve the speed of the welding process significantly. It allows you to weld at a higher speed without compromising the quality of the joint. It also boosts the production rate, making it perfect for industrial applications with large-scale production requirements.

4. Material Thickness

The traditional welding method is applicable to various materials with variable thickness. However, using traditional welding on certain materials and thin sheets results in issues like warping and deformation. These issues damage the end results, leaving you with unwanted products.

On the other hand, employing hybrid laser welding is a better option for dealing with various materials and thin sheets. Its deep penetration and narrow weld bead allow you to work with several materials, like steel, nickel, and aluminum alloys. It also allows you to weld material of variable thickness. The integration of arc and laser welding allows you to weld thin materials as well as thicker workpieces.

Applications of Hybrid Laser Welding

Hybrid laser welding is a versatile welding approach that is used in several industries. The following are some applications of hybrid welding:

1. Transport Industry

Transport is a vast industry that requires durable solutions. Hybrid welding is extensively employed in the automotive industry to weld various components of vehicles. The precision and better speed of laser welding coupled with the deep penetration of traditional arc welding makes hybrid welding a suitable match to manufacture reliable welds of vehicles.

Moreover, hybrid welding also helps in minimizing the weight of vehicles. Weight is a prominent factor in improving cargo capacity. It also contributes to lower energy expenditure, resulting in fuel efficiency. The integration of hybrid welding in the transport industry provides lightweight and durable solutions.

2. Shipbuilding

Shipbuilding is another extensive industry that relies on the precision of welded components for its smooth operations. Achieving precise results is crucial to avoid any potential hazards.

Hybrid laser welding enables manufacturers to deal with thin materials and lightweight designs. Maintenance of high-speed and greater production rates also allows you to construct huge structural components in a short time. This technique also limits the distortion of materials, leading to improved structural integrity.

3. Construction

Hybrid laser welding is a crucial technique for the construction industry. The fabrication of steel structures, such as bridges, pipelines, and buildings, requires durable connections. You can also work with thick steel sheets that are difficult to weld using traditional methods. Any slight error in welding can significantly affect the structural integrity of the entire building.

The integration of laser and arc welding in hybrid welding offers durable welds with minimum distortion and higher production rates. It also contributes to the durability of the structures for rough usage.

4. Energy Sector

The energy sector involves the construction of large turbines, generators, and several other components for electricity generation. Faults in the construction of these components not only result in the wastage of resources but also pose significant safety hazards.

Employing hybrid laser welding in this sector offers better speed, helping in mass production in a limited duration. It also ensures excellent tolerance to joint gaps to eliminate the risks of any weak points in the components. Consistent welds with high efficiency contribute to the overall safety and reliability of energy production.

5. Mobile Equipment

The mobile equipment industry is a massive contributor to the global economy. The industry involves manufacturing heavy-duty vehicles like mining machinery, cranes, and agricultural machines. Narrow and deep seams in this type of equipment are a challenge while working with traditional welding techniques.

Integrating laser welding with traditional arc welding in hybrid welding allows you to work with these intricate structures and precise designs of these mobile equipment. Moreover, hybrid welding helps in joining dissimilar materials for optimal performance of the machinery.

Challenges and Considerations

Though hybrid laser welding offers numerous benefits, it also comes with some challenges. Here are some challenges and considerations to consider while implementing hybrid laser welding.

1. Inaccuracy in Weld Formation

Hybrid laser welding is a precise technique that involves high-speed production. However, this high speed can deteriorate your workpiece if not controlled. A monitoring system is necessary to maintain the required speed while ensuring the quality of welds. Integrating an automated monitoring system can improve the welding process without compromising the productivity of the process.

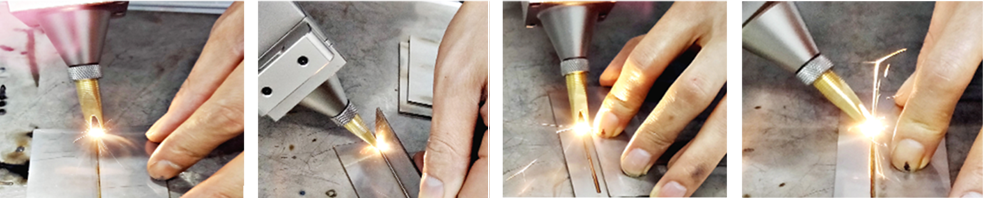

2. Improper Handling

Hybrid laser welding is a complex process due to the involvement of two welding methods. It requires training and precise handling to avoid any mishaps. Manufacturers need to train workers to handle the welding equipment and ensure that all safety precautions are followed to prevent any accidents.

3. Heat Buildup

Hybrid welding employs a high-energy laser beam and heat from an electric arc. The dual energy source can significantly increase the temperature of the working station. Excessive heat can cause thermal distortion to the workpiece, leading to inaccurate welds.

It can also affect the safety of the workers. To avoid potential hazards, maintaining a well-ventilated space is crucial. Ventilation eliminates unwanted heat from the welding site, providing a safe and healthy working environment.

4. Safety Hazards

Hybrid laser welding poses several safety risks to workers dealing with welded workpieces. Exposure to the intense laser beams can pose health risks to workers. The laser beam can elevate the risks of cancer and chronic diseases if not handled correctly. Wearing safety goggles and other safety gear can minimize the risk of exposure to the laser beam.

Future of Hybrid Laser Welding

Hybrid laser welding is a contributing technology that promises precision and quality welds. The innovative approaches in hybrid welding are continuously evolving to enhance the process’s performance and capabilities. Its ability to cater to different thicknesses and materials makes it a highly sought-after technology for several industries.

Moreover, the high speed and effective heat control capabilities of hybrid welding make it a desirable choice for mass production. Its efficiency and effectiveness make it a leading technology in the welding industry, promising a bright future for hybrid laser welding.

FAQs

1. Is laser welding stronger than MIG?

Yes, laser welding is about 3 to 10 times stronger than MIG. Laser welding employs a high-energy laser beam that penetrates the workpiece, giving you the desired results.

2. How fast is laser hybrid welding?

The speed for laser hybrid welding varies. With this technique, you can cut an 8mm thick steel at a speed of 0.8 m/min.

3. What is the difference between traditional welding and laser welding?

Traditional welding employs heat energy from an electric arc or gas flow. In contrast, laser welding employs intense laser beams for welding purposes. Laser is known for better quality welds due to its precision and accuracy, while traditional welding is known for its versatility in welding thick plates.

Conclusion

Hybrid welding has emerged as a spectacular addition to the welding industry. This welding approach is known for its deeper penetration into the workpiece and higher fatigue resistance. Hybrid welding helps reduce welding costs, making it a cost-effective technique for several industries. Choose a high-end laser solution with hybrid laser welding to get the required results.

Unleash the Potential of Hybrid Laser Welding with Comwelder Laser!

A high-precision laser welder is necessary for conducting hybrid laser welding. Comwelder Laser is one of the best providers of laser solutions, get a laser welding machine and integrate it with your traditional welding machine for the best results.

Contact us today for high-quality laser solutions catering to your welding needs. Our team of experts will offer you the best solution for your project.