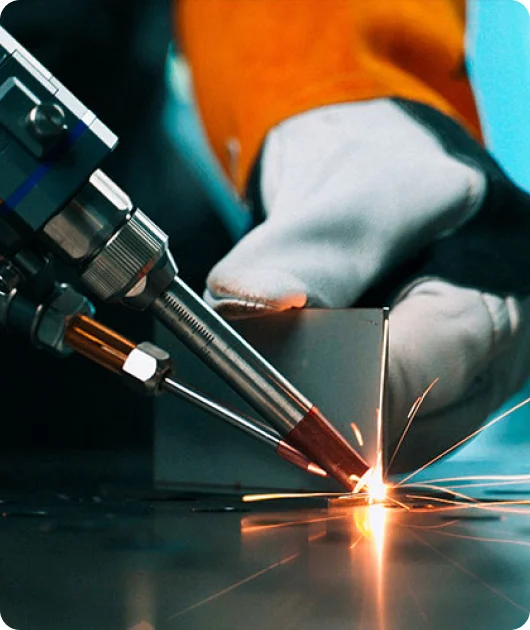

Fiber Laser Welding

Fiber laser welding, like other laser-machining methods, is a non-contact technology that has a limited, heat-affected zone (HAZ), which is why the technology is a preferred method for welding delicate products at high speeds. Laser welding is also a more repeatable and consistent process than other welding methods, and is capable of producing high-strength bonds without the need for filler material, flux, prepping, or secondary cleaning and finishing processes. Fiber Laser Welding has enabled many applications, such as energy storage with lithium ion batteries and implantable medical devices, to be manufactured in extreme scales, at much lower costs, with greater consistency, at greater speeds, and with much less waste and quality-control issues. Moreover, a laser welding manufacturing process is much more reliable than other welding technologies, as the latest laser-welding machines require little to no maintenance, and virtually no downtime.

What is laser radiation?

What is laser light?

Laser Light: It travels at 299.792.458 meters per sec. Its spectrum ranges from 100 to 1400 nanometers. It is light, and its smallest unit is a packet of energy: a photon.

In most of its natural and artificial forms, light has little power. However, a groundbreaking invention in the latter half of the 1950s increased its power and concentrated it in a small area. Thus was born a modern and revolutionary concept:

Light Amplification by Stimulated Emission of Radiation, or L.A.S.E.R.

The laser as a heating source

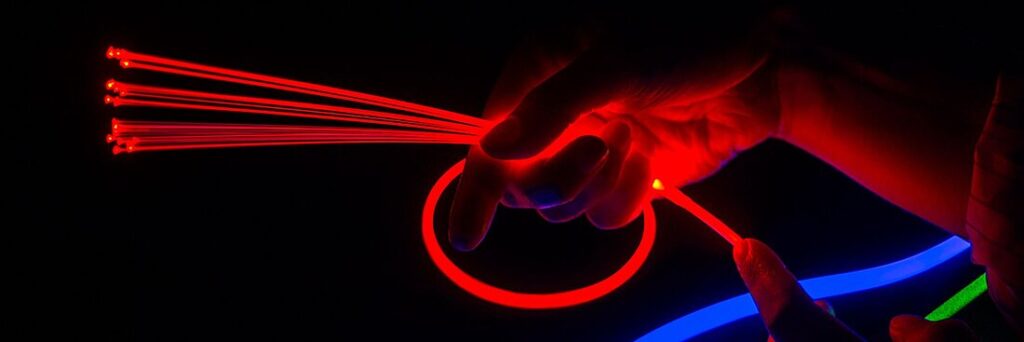

Laser welding requires that the laser raise the temperature of the material to be welded. The fiber laser light must be absorbed by the material to induce a temperature rise. In effect, the fiber laser light beam is focused onto the material similar to the way the sun can be focused by a magnifying glass. The difference is that the laser’s power density is many orders of magnitude higher.

Laser light photons, packets of light energy that make up the laser, impinge onto the material and are partly or wholly absorbed. The energy of the photon is absorbed in the metal material and causes a heat waves within the metal. Repeated absorption of photons eventually leads to metal surface breakup and melting.

Even for metals that absorb well, such as steel, the laser is initially reflected. A small percentage of the laser is absorbed, heating the metal surface. The increased surface temperature increases the absorption of the fiber laser light photons. This creates a snowball effect, in which the material is rapidly heated by the laser, leading to melting and formation of the weld.

Fiber Laser Welding

Unlimited possibilities

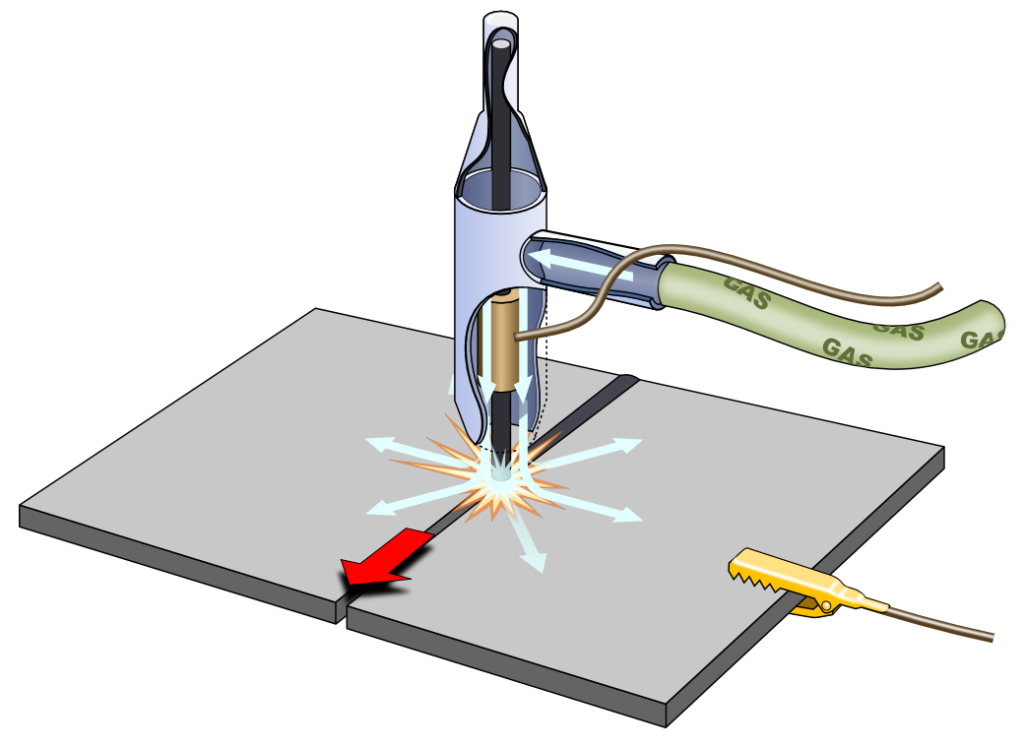

Laser Welding is a welding technology used to join several metal components. A laser produces a beam of high-intensity that is concentrated into one spot. This concentrated heat source enables fine, deep welding and high welding speeds.

Traditional but old laser welding technologies, such as

continuous-wave CO2 welding lasers are limited in terms of accuracy and undesired, high heat input into the weld and

the traditional pulsed Nd:YAG welding lasers are limited by the maximum welding speed, the minimal spot size that can be achieved and the electrical to optical energy conversion efficiency that is very bad.

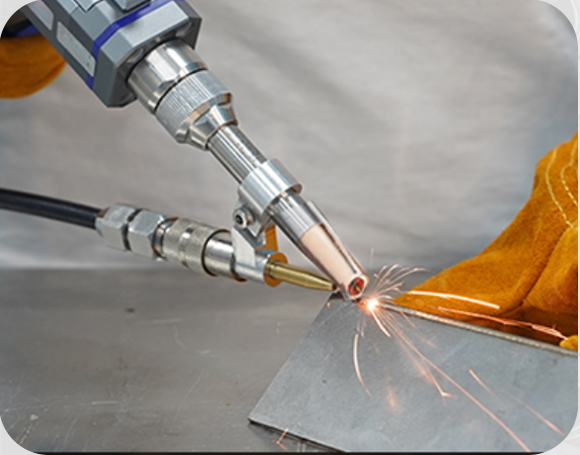

With the latest fiber laser welding, the output power and the oscillation form of the laser beam is possible to change. Fiber Laser Welding is also very suitable for welding materials with a high melting point or with high thermal conductivity due to a very low thermal effect during welding. The energy conversion rate is very high and all this makes fiber laser highly adaptable to various applications for use in various welding assembly processes.

The fiber laser beam used for welding can be adapted as follows and characterized by different laser oscillation modes :

Pulsed laser beam welding (ideal for spot welding) and Continuous laser beam welding (ideal for seam welding)

Even more applications are demanding a higher precision control, lower heat input and lower electrical energy consumption.

Fiber Laser Welding is a technology that offers optimal solution for both: spot welding AND Seam Welding.

Laser welding does not operate on the same principles as other types of welding like TIG, MIG, MAG,..

Laser welding uses a beam of light, instead of electricity, to join two pieces of metal together through a melting and cooling process.

Another key difference with laser welding is the intensity and ability to focus the heat source: the laser. The much higher, focused heat than, say, the electricity of a MIG welder or TIG welder, means that the weld occurs much more quickly. What’s more, the ability to narrowly pinpoint the weld area leads to much greater precision and more accurate and attractive weld joints.

What does this mean for you?

Higher speeds: till 10x faster than MIG welding, and till 40x faster than TIG welding.

Minimal/no finishing: The accuracy of the laser welding process means that little to no grinding or finishing is needed.

Visually superior: Laser welding is ideal for straight line joints in furniture and other consumer products, since there is a much smaller heat-affected zone and a much tighter weld.

Greater strength: A smaller heat-affected zone also means less weakening of the material.

So when wouldn’t you want to use laser welding? Thicker materials and parts where the weld joint construction does not allow the fit-up to be consistently maintained generally are not good candidates for laser welding.